English

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

| Effective Volume: | Please select |

|---|---|

| Optional Configuration: | |

| Availability: | |

| Quantity: | |

• Smart

Mini scale industrial brewing equipment, with all the scaled down parts&fittings, you will full in love with this optimized Brew center.Installed& wiring ready on a fully welded frame platform, nothing can be easier for your pilot beer brewing jobs.

• 100% Flexible Design

Introduction

100L 3-Vessel Brewhouse System | ||

| Product Name | 100L Brewhouse |

Components | Right: Mash+ Lauter Tank | |

Middle: Kettle + Whirlpool Tank | ||

Left: Hot Water Tank | ||

Dimension | 2500mm(L)*1100mm(W)*1650mm(H) | |

Weight | 400kg | |

Installation Method | Assembled ready to use, Removable | |

Heating Method | Build-in Electric Elements | |

Consuming power | 13.1kw | |

Operability | Easy | |

Control System | PID Control | |

Application | Larger, Ale, IPA, Creative pilot Craft Beer | |

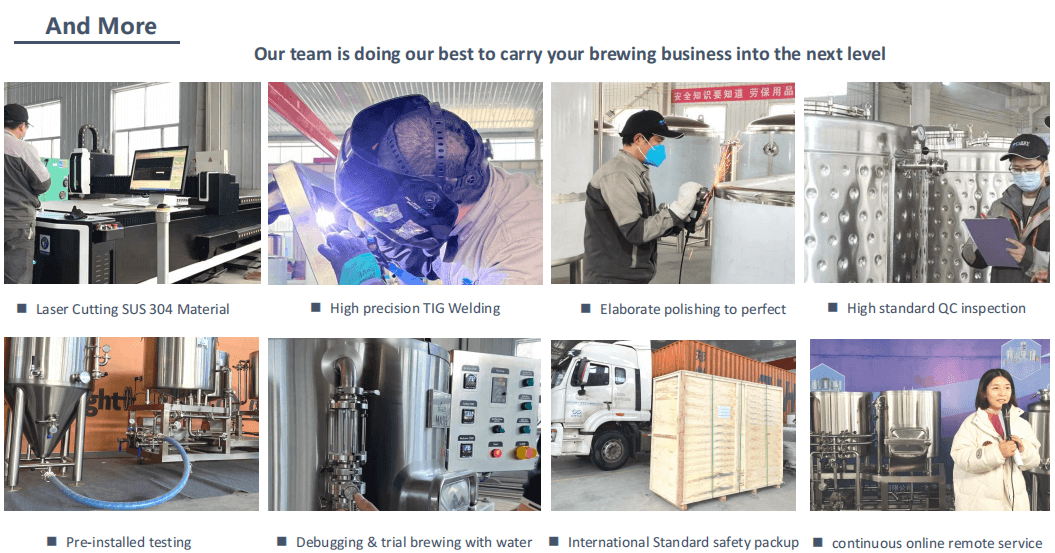

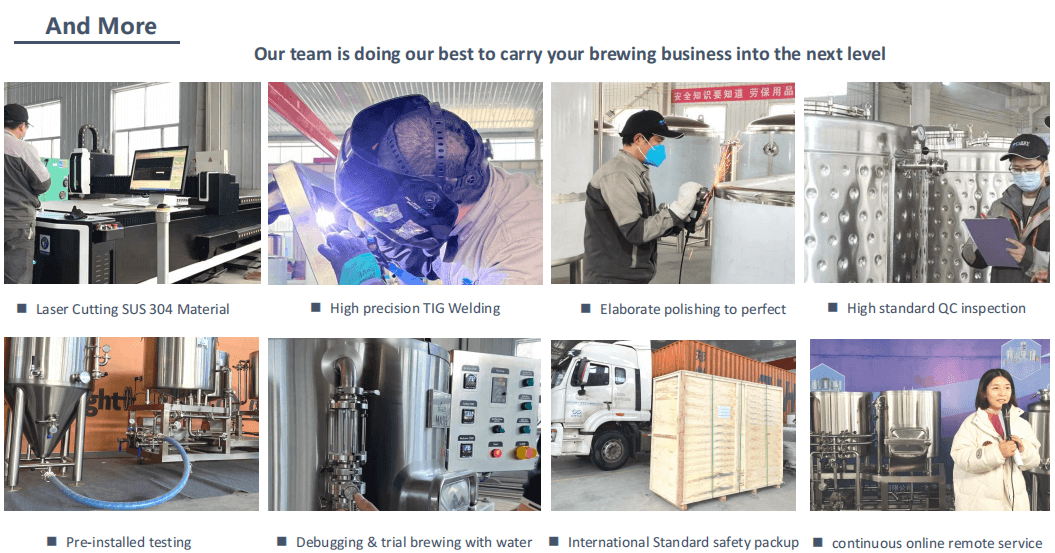

Production Technology | ||

1. Inner-Jacket (SUS304), TH=3.0mm, pickling&passivating treated; 2. External-Jacket(SUS 304), TH=2.0mm, ink wires drawing plate 3. Atmosphere pressure lid, TH=3.0mm 4. Tanks’ Insulation layer: PU-thickness= 30mm. 5. 100% high precision TIG welded joints 6. Strong universal wheels (with shaft) | ||

PID Control panel

Manual open top lid

grain outdoor & chute

Valve trees

Wort pump with manifold

Temperature Probe(Tri-clamp)

heating elements(Tri-clamp)

Sight glass

Whirlpool Inlet

Semi-automatic Control System

Never give up your creative recipe with such a smart control system, temperature control, pump VFD speed control, international standard electric components takes your brewing into the next level.

• Optional System power supply 110V/220V/380V/415V

• Total Frame mounted structure, convenient to move around

| A. Anti-dry burning liquid level sensor | B. RIMS | ||

| · Liquid Level Sensor Suggest installing in the tank where you have electric heating elements, your control cabinet will alarm if heating without enough water |  | ·Installed underneath the mash/lauter tank, along with wort outlet pipeline ·with 1 x 3kw electric heating element ·realize multiple steps mashing recipes if needed |

| Buy Together |

Smart Chiller Unit

100L Fermentation Tank

• Smart

Mini scale industrial brewing equipment, with all the scaled down parts&fittings, you will full in love with this optimized Brew center.Installed& wiring ready on a fully welded frame platform, nothing can be easier for your pilot beer brewing jobs.

• 100% Flexible Design

Introduction

100L 3-Vessel Brewhouse System | ||

| Product Name | 100L Brewhouse |

Components | Right: Mash+ Lauter Tank | |

Middle: Kettle + Whirlpool Tank | ||

Left: Hot Water Tank | ||

Dimension | 2500mm(L)*1100mm(W)*1650mm(H) | |

Weight | 400kg | |

Installation Method | Assembled ready to use, Removable | |

Heating Method | Build-in Electric Elements | |

Consuming power | 13.1kw | |

Operability | Easy | |

Control System | PID Control | |

Application | Larger, Ale, IPA, Creative pilot Craft Beer | |

Production Technology | ||

1. Inner-Jacket (SUS304), TH=3.0mm, pickling&passivating treated; 2. External-Jacket(SUS 304), TH=2.0mm, ink wires drawing plate 3. Atmosphere pressure lid, TH=3.0mm 4. Tanks’ Insulation layer: PU-thickness= 30mm. 5. 100% high precision TIG welded joints 6. Strong universal wheels (with shaft) | ||

PID Control panel

Manual open top lid

grain outdoor & chute

Valve trees

Wort pump with manifold

Temperature Probe(Tri-clamp)

heating elements(Tri-clamp)

Sight glass

Whirlpool Inlet

Semi-automatic Control System

Never give up your creative recipe with such a smart control system, temperature control, pump VFD speed control, international standard electric components takes your brewing into the next level.

• Optional System power supply 110V/220V/380V/415V

• Total Frame mounted structure, convenient to move around

| A. Anti-dry burning liquid level sensor | B. RIMS | ||

| · Liquid Level Sensor Suggest installing in the tank where you have electric heating elements, your control cabinet will alarm if heating without enough water |  | ·Installed underneath the mash/lauter tank, along with wort outlet pipeline ·with 1 x 3kw electric heating element ·realize multiple steps mashing recipes if needed |

| Buy Together |

Smart Chiller Unit

100L Fermentation Tank