English

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

| Effective Volume: | Please select |

|---|---|

| Heating Method: | Please select |

| Availability: | |

| Quantity: | |

CARRY Brewtech 200LSTAR Nano Brewery Equipment is specially customized for homebrew hobbies, entry-level Micro Breweries, Pilot Brewing System, or a full-scale Nano-Brewery production.

Smart

Mini scale industrial brewing equipment, with all the scaled down parts&fittings, you will full in love with this optimized Brew center.

Turnkey Solution

Installed& wiring ready on a fully welded frame platform, nothing can be easier for your pilot beer brewing jobs

Cost-effective

The 200L Brewhouse saves space and your installation time. It has four wheels and is very convenient to move. All Tanks are on one frame, which is very compact and practical.

Mash+Lauter Tank

1. Effective volume=200L, max volume=250L

2. Atmospheric top lid

3. Tri-clamp Spary Ring Tube

4. Wort backflow pipeline equip with Sight glass

5. Removable false bottom

6. Grain out door 7. Temperature Probe&PT-100

Kettle+Whirlpool Tank

1. Effective volume=200L, max volume=250L

2. Atmospheric pressure lid

3. 6kw electric element

4. Tangent whirlpool inlet

5. Temperature Probe&PT-100

Hot Water Tank

1. Effective volume=200L, max volume=280L

2. Atmospheric manual open top lid3. 12kw electric element

4. With 1T/H Hot water pump

5. Temperature Probe&PT-100

6. with level mark inside of tank

PID Control Cabinet

1. SUS 304 Material cabinet

2. Temperature indicator & heating elements on/off control of mash/lauter tun, kettle/whirlpool tank, hot water tank

3. Wort Pump VFD Speed control

4. Hot water pump on/off control

5. With high quality electric components, Schneider brand. CE, ISO Certificated

Knocking Out Fittings

1. High precision hops filter, equipped in pipelinebefore PHE

2. 3㎡ single stage plate heat exchanger

3. Temperature Gauge after PHE

4. Tap water outlet from the PHE to be able backflow into Hot water tank

5. Oxygenation device before wort knocking out port

|  |

|  |

| Brewhouse from view | Backflow baffle/ Easy clean and detachable sparging spray ring | High quality Sieve in mash/lauter tank | VFD Wort Pump(Flow capacity=1T/h) |

|  |

|  |

| Electric elementes used in kettle/whirlpool tank&HLT | Tangent Whirlpool inlet for kettle/whirlpool tank | Temoerature proble& PT-100 | Plate Heat Exchanger |

|  |  |  |

| PID Controller | Sight Glass | Grain out door + grain chute | Strong universal wheels |

Saccharification flow chart:

step 1: Put the Malt into the Malt miller; in this step can make the malt fully mashed.

step 2: Mix and stir the pulverized malt with 63-68° water, and use the enzymes contained in the malt to decompose the insoluble macromolecular substances (starch, protein, hemicellulose, etc.) in the malt and auxiliary materials into soluble low-molecular-weight substances. (eg sugars, dextrins, amino acids, peptides), in this step we can get the wort.

step 3: The next step is Lauter. In this step, we need to add water at 78-82° twice to wash the wort. Then we will filter to get clear wort. This step can be observed through our sight glass.

step 4: The next step is to boil and spin sink. Through this step, we sterilize the wort. The purpose of the spin sink is to precipitate the deteriorated protein in the wort, so that we can get a clearer wort.

Relative Products

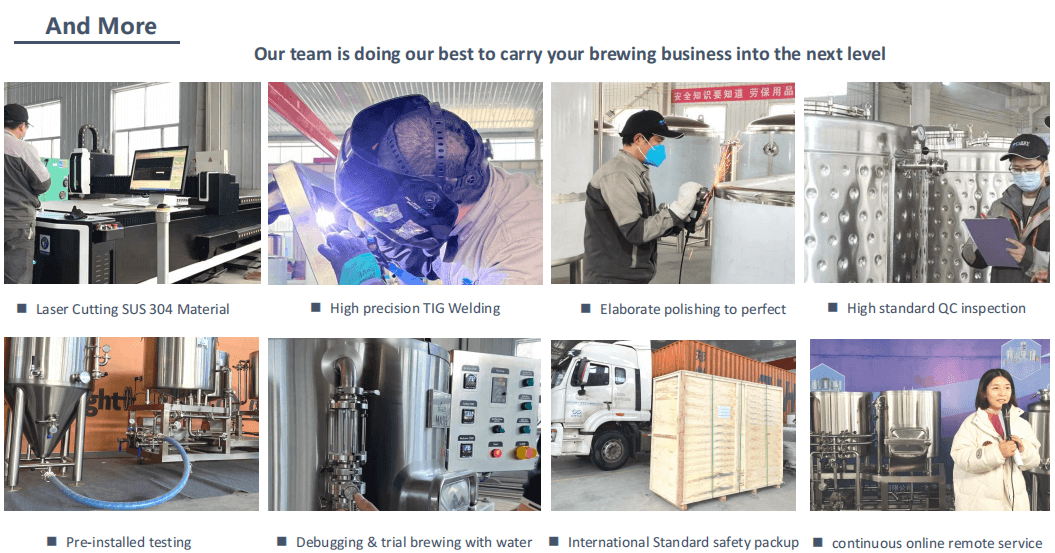

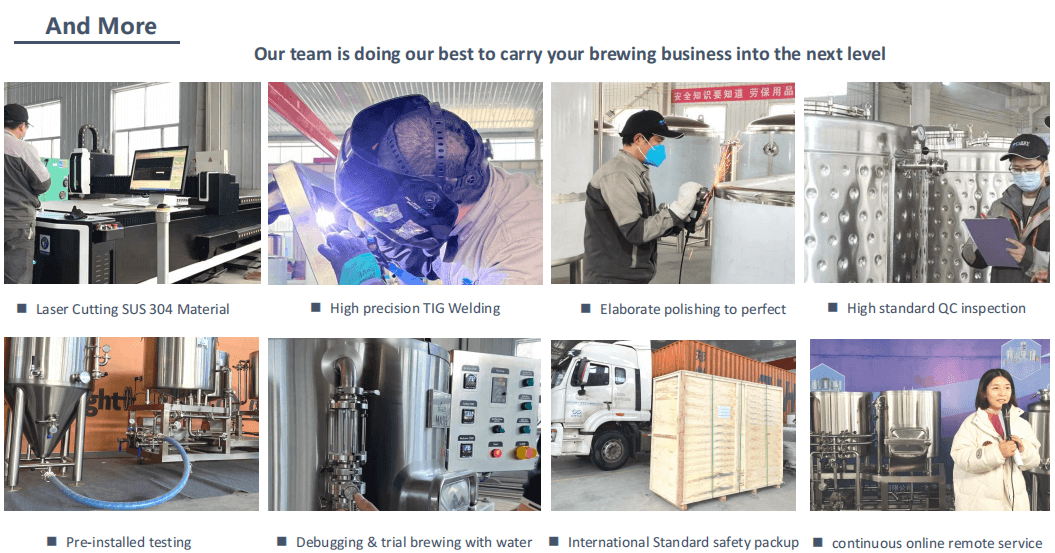

All equipment are protected with film and safty cotton

When loaded into the crate, they will be fasterned as tight as we can

Direct shipment from our factory, safe and fast

Direct shipment from our factory, safe and fast

Shandong Carry Equipment Co., Ltd

Carry Equipment is a professional brewing equipment supplier in China. We have own factory and technology team. The staff has more than 10 years brewing experience and manufacturing experience.

CARRY Brewtech 200LSTAR Nano Brewery Equipment is specially customized for homebrew hobbies, entry-level Micro Breweries, Pilot Brewing System, or a full-scale Nano-Brewery production.

Smart

Mini scale industrial brewing equipment, with all the scaled down parts&fittings, you will full in love with this optimized Brew center.

Turnkey Solution

Installed& wiring ready on a fully welded frame platform, nothing can be easier for your pilot beer brewing jobs

Cost-effective

The 200L Brewhouse saves space and your installation time. It has four wheels and is very convenient to move. All Tanks are on one frame, which is very compact and practical.

Mash+Lauter Tank

1. Effective volume=200L, max volume=250L

2. Atmospheric top lid

3. Tri-clamp Spary Ring Tube

4. Wort backflow pipeline equip with Sight glass

5. Removable false bottom

6. Grain out door 7. Temperature Probe&PT-100

Kettle+Whirlpool Tank

1. Effective volume=200L, max volume=250L

2. Atmospheric pressure lid

3. 6kw electric element

4. Tangent whirlpool inlet

5. Temperature Probe&PT-100

Hot Water Tank

1. Effective volume=200L, max volume=280L

2. Atmospheric manual open top lid3. 12kw electric element

4. With 1T/H Hot water pump

5. Temperature Probe&PT-100

6. with level mark inside of tank

PID Control Cabinet

1. SUS 304 Material cabinet

2. Temperature indicator & heating elements on/off control of mash/lauter tun, kettle/whirlpool tank, hot water tank

3. Wort Pump VFD Speed control

4. Hot water pump on/off control

5. With high quality electric components, Schneider brand. CE, ISO Certificated

Knocking Out Fittings

1. High precision hops filter, equipped in pipelinebefore PHE

2. 3㎡ single stage plate heat exchanger

3. Temperature Gauge after PHE

4. Tap water outlet from the PHE to be able backflow into Hot water tank

5. Oxygenation device before wort knocking out port

|  |

|  |

| Brewhouse from view | Backflow baffle/ Easy clean and detachable sparging spray ring | High quality Sieve in mash/lauter tank | VFD Wort Pump(Flow capacity=1T/h) |

|  |

|  |

| Electric elementes used in kettle/whirlpool tank&HLT | Tangent Whirlpool inlet for kettle/whirlpool tank | Temoerature proble& PT-100 | Plate Heat Exchanger |

|  |  |  |

| PID Controller | Sight Glass | Grain out door + grain chute | Strong universal wheels |

Saccharification flow chart:

step 1: Put the Malt into the Malt miller; in this step can make the malt fully mashed.

step 2: Mix and stir the pulverized malt with 63-68° water, and use the enzymes contained in the malt to decompose the insoluble macromolecular substances (starch, protein, hemicellulose, etc.) in the malt and auxiliary materials into soluble low-molecular-weight substances. (eg sugars, dextrins, amino acids, peptides), in this step we can get the wort.

step 3: The next step is Lauter. In this step, we need to add water at 78-82° twice to wash the wort. Then we will filter to get clear wort. This step can be observed through our sight glass.

step 4: The next step is to boil and spin sink. Through this step, we sterilize the wort. The purpose of the spin sink is to precipitate the deteriorated protein in the wort, so that we can get a clearer wort.

Relative Products

All equipment are protected with film and safty cotton

When loaded into the crate, they will be fasterned as tight as we can

Direct shipment from our factory, safe and fast

Direct shipment from our factory, safe and fast

Shandong Carry Equipment Co., Ltd

Carry Equipment is a professional brewing equipment supplier in China. We have own factory and technology team. The staff has more than 10 years brewing experience and manufacturing experience.