English

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

| Volume: | |

|---|---|

| Heating Method: | Please select |

| Availability: | |

| Quantity: | |

The main equipment of a complete set of 500L beer brewing system is shown in the table below:

| 500L Beer Brewery System | |

1. 200kg/h Malt miller | 2. 500L Brewhouse, steam heating |

3. 1000L Hot liquid tank | 4. Steam boiler with salt tank&water tank |

5. 500L*6 Fermentation tanks with dry hops adding port | 6. 300L*2 Fermentation tanks with dry hops adding port |

7. 500L Bright beer tank | 8. 1500L Glycol water tank |

| 9. 3HP*2 Chiller | 10. 3T/H Glaycol water pump |

11. Brewing and fermenting control cabinet | 12. 50L*2 CIP carts |

Beer Brewing System

500L Brewhouse

500L Brewhouse

* Mash&Lauter Tank Effective Volume=500L

* Kettle&Whirlpool Tank Effective Volume=500L

* Brewhouse Control Cabinet

* VFD Motor with Raker

* Plateform with handrails

* Plate Heating Exchanger

* Condensing Unit

* Level Gauge

* Wort Collection Pipe

* Back Flushing Pipe

Steam Boiler

* Steam generator capacity=50kg/h

* Famous brand YANO, International Quality Standard

* Consuming power=3kw

* With water softener

* With pressure relief safety valve

* With salt tank

* With indivuidual pressure & steam flow control system

* Dimension is 880mm*800mm*1300mm

* Grass weight is 250kg

1000L Hot liquid tank

* Effective volume=1000L

* Total volume=1250L

* Dimension=φ1160mm*2000mm

* Top glass manway

* Steam heating jacket

* Pressure relief valve

* Level tube indicator

* With 3T/H hot water pump

Fermenting System

500L Fermentation Tank

* Effective Volume=500L

* Total Volume=625L

* Sampling Valve

* Carbonation Valve

* CO2 blow off arm with Spunding Valve

* CIP Arm with 360° CIP ball & Pressure Gauge

* Dry Hops Adding port

* Dry Hops Adding device

* Rotary Racking Arm

* Lifting Lugs

* Beer outlet & Drain outlet

500L Bright Beer Tank

* Effective Volume=500L

* Total Volume=625L

* Net Dimension: Φ1060 * 1750mm

* 360° spray ball and pressure gauge equip with CIP arm

* Spunding vavle on CO2 blow off arm

* Sample Valve

* Temperature probe: PT-100

* Carbonation Stone

* Level Tube

* Beer outlet

Cooling System

1500l Glycol Water Tank

* Effective volume:1500L, total volume: 1650L

* Net Dimension=Φ1360 *2100mm

* Level tube

* Insulated conical top and sloped bottom

* Glycol water inlet and outlet

* Inner-jacket (SUS304) thickness: 3mm, pickling and passivating treated; External-Jacket(SUS304) thickness: 2mm, Hairline polishing;

* Insulation layer: PU-thickness= 80mm.

* 100% high accuracy TIG welding.

3HP Chiller

* 3HP, Working power: 2.8 KW/unit.

* Internal compressor brand is USA Copeland.

* Copland vortex compressor, more durable, refrigeration effect

* Medium: Environmental protection refrigerants R404A

* Dimension=900*800*750mm

Auxiliary Machine Series

Beer Kegs

Filler And Caper

Kegs Washing Machine

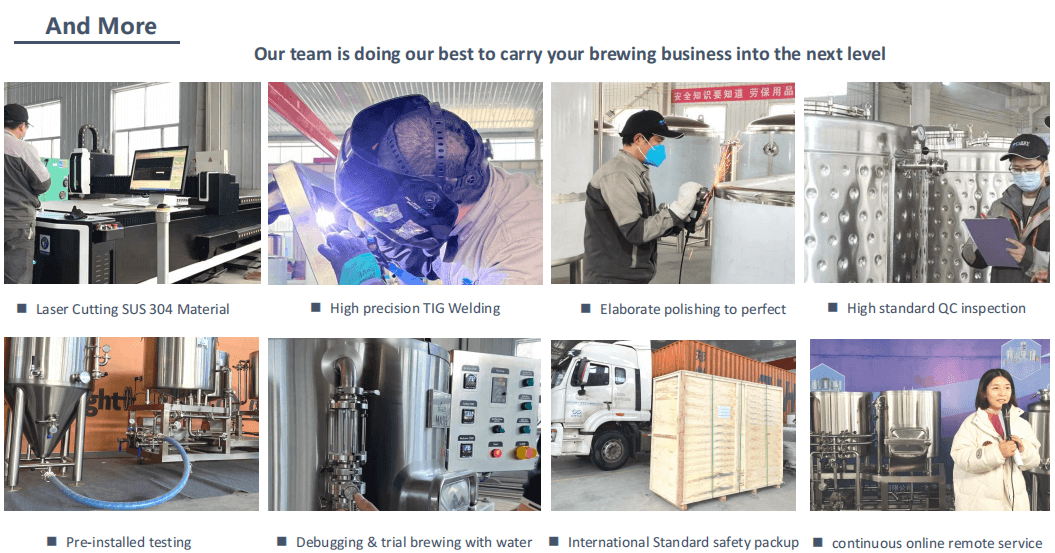

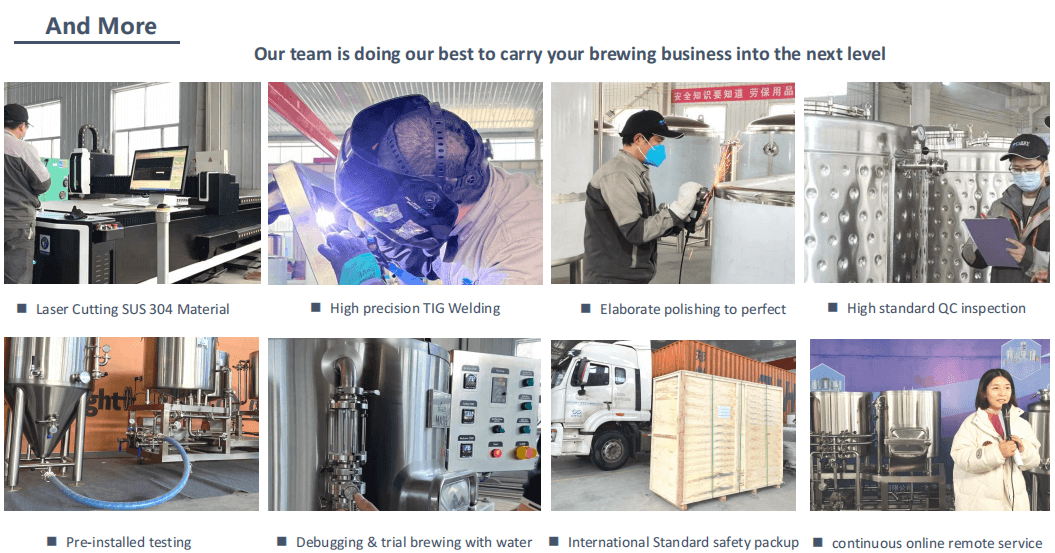

All equipment must be tested and piped in our factory before delivery.

Labels will be attached to the interface and pipes to explain the connected accessories and the direction of the pipes. After receiving the equipment, install the pipes and accessories according to the labels, it's as easy as a puzzle.

The main equipment of a complete set of 500L beer brewing system is shown in the table below:

| 500L Beer Brewery System | |

1. 200kg/h Malt miller | 2. 500L Brewhouse, steam heating |

3. 1000L Hot liquid tank | 4. Steam boiler with salt tank&water tank |

5. 500L*6 Fermentation tanks with dry hops adding port | 6. 300L*2 Fermentation tanks with dry hops adding port |

7. 500L Bright beer tank | 8. 1500L Glycol water tank |

| 9. 3HP*2 Chiller | 10. 3T/H Glaycol water pump |

11. Brewing and fermenting control cabinet | 12. 50L*2 CIP carts |

Beer Brewing System

500L Brewhouse

500L Brewhouse

* Mash&Lauter Tank Effective Volume=500L

* Kettle&Whirlpool Tank Effective Volume=500L

* Brewhouse Control Cabinet

* VFD Motor with Raker

* Plateform with handrails

* Plate Heating Exchanger

* Condensing Unit

* Level Gauge

* Wort Collection Pipe

* Back Flushing Pipe

Steam Boiler

* Steam generator capacity=50kg/h

* Famous brand YANO, International Quality Standard

* Consuming power=3kw

* With water softener

* With pressure relief safety valve

* With salt tank

* With indivuidual pressure & steam flow control system

* Dimension is 880mm*800mm*1300mm

* Grass weight is 250kg

1000L Hot liquid tank

* Effective volume=1000L

* Total volume=1250L

* Dimension=φ1160mm*2000mm

* Top glass manway

* Steam heating jacket

* Pressure relief valve

* Level tube indicator

* With 3T/H hot water pump

Fermenting System

500L Fermentation Tank

* Effective Volume=500L

* Total Volume=625L

* Sampling Valve

* Carbonation Valve

* CO2 blow off arm with Spunding Valve

* CIP Arm with 360° CIP ball & Pressure Gauge

* Dry Hops Adding port

* Dry Hops Adding device

* Rotary Racking Arm

* Lifting Lugs

* Beer outlet & Drain outlet

500L Bright Beer Tank

* Effective Volume=500L

* Total Volume=625L

* Net Dimension: Φ1060 * 1750mm

* 360° spray ball and pressure gauge equip with CIP arm

* Spunding vavle on CO2 blow off arm

* Sample Valve

* Temperature probe: PT-100

* Carbonation Stone

* Level Tube

* Beer outlet

Cooling System

1500l Glycol Water Tank

* Effective volume:1500L, total volume: 1650L

* Net Dimension=Φ1360 *2100mm

* Level tube

* Insulated conical top and sloped bottom

* Glycol water inlet and outlet

* Inner-jacket (SUS304) thickness: 3mm, pickling and passivating treated; External-Jacket(SUS304) thickness: 2mm, Hairline polishing;

* Insulation layer: PU-thickness= 80mm.

* 100% high accuracy TIG welding.

3HP Chiller

* 3HP, Working power: 2.8 KW/unit.

* Internal compressor brand is USA Copeland.

* Copland vortex compressor, more durable, refrigeration effect

* Medium: Environmental protection refrigerants R404A

* Dimension=900*800*750mm

Auxiliary Machine Series

Beer Kegs

Filler And Caper

Kegs Washing Machine

All equipment must be tested and piped in our factory before delivery.

Labels will be attached to the interface and pipes to explain the connected accessories and the direction of the pipes. After receiving the equipment, install the pipes and accessories according to the labels, it's as easy as a puzzle.