English

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

| Effective Volume: | Please select |

|---|---|

| Optional Configuration: | Please select |

| Availability: | |

| Quantity: | |

CARRY Brewtech 100L Pilot Brewing Equipment Brewing Kit is specially customized for homebrew hobbies, entry-level Micro Breweries, Pilot Brewing System, or a full-scale Nano-Brewery production.

Configuration:

Regarding the picture, that is customized 100L 3 vessel brewhouse.

-With Mash/Lauter tank, Kettle/Whirlpool Tank, Hot Liquor Tank, all tanks are 2-layer with insulation

--Mash tank is with false bottom, grain door, and so on

--Kettle tank is with whirlpool tangential inlet, electric element, and so on

--Hot liquor tank is with electric element mainly.

--With PLC controller

Hot Liquor Tank

Kettle/Whirlpool Tank

Mash/Lauter Tank

Heating method:

Standard brewhouse is heated by electric elements.

When brewing with electric, the heat is applied internally rather than externally (as with direct fire or steam jacket). The heating comes from electric elements which are housed in stainless steel sheathes inserted in your brewhouse vessels.

The main vessels in our brewhouse electric elements are kettle/whirlpool tank and hot liquor tank (HLT). You can have electric heating for your mash tun too. However, that’s a little trickier requiring its own section. Thus we suppgest that RIMS can help you in mash tank part.

Since, the elements are immersed in the liquid, virtually all of the energy applied to the elements, is transferred to heating your wort or water. Depending on the size of the brewhouse, you’ll usually have different KW elements per tank. Our 100L brewhouse is with 6kw electric elements for each tank.

Please don’t hesitate to contact us if you are interested in electric elements, looking forward to providing you with more services and support.

Comparing standard 100L brewhouse, ther are some difference as followsfor this customized 100L brewhouse:

1-Controller is changed. Generally it is with PID controller, this set is changed to PLC controller according to customers' requests

2-Add RIMS. That is more beneficial for brewers who like stepped mashing

3-Add Raker and Raker Motor. Standard brewhouse isn't fitted with raker motor, we will match a rake for you, and you can stir your wort by this rake

4-Position of electricity box is changed, Standard box is inside of the plateform frame, but PLC's box is too big to put it outside of the plateform frame

5-Updated Hop filter, and in the following days, this type will be our standard confirguration

PLC Controller

RIMS

Raker with Motor

Position of electricity box

Updated Hop Filter-Internal structure

Updated Hop Filter-External structure

Advantages

• Optional system volume from 100L to 200L

• Optional System power supply 110V/220V/380V/415V

• Total Frame mounted structure, convenient to move around

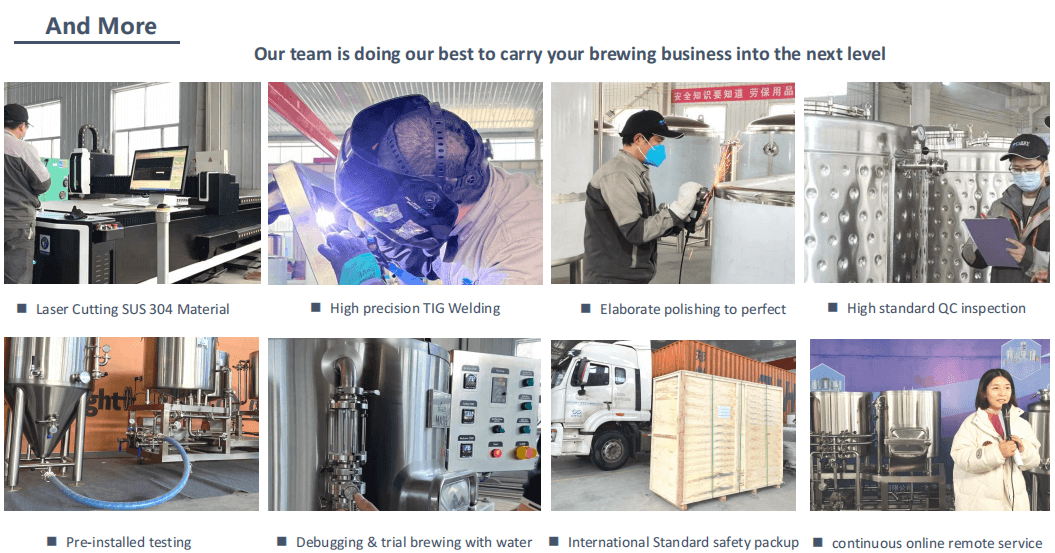

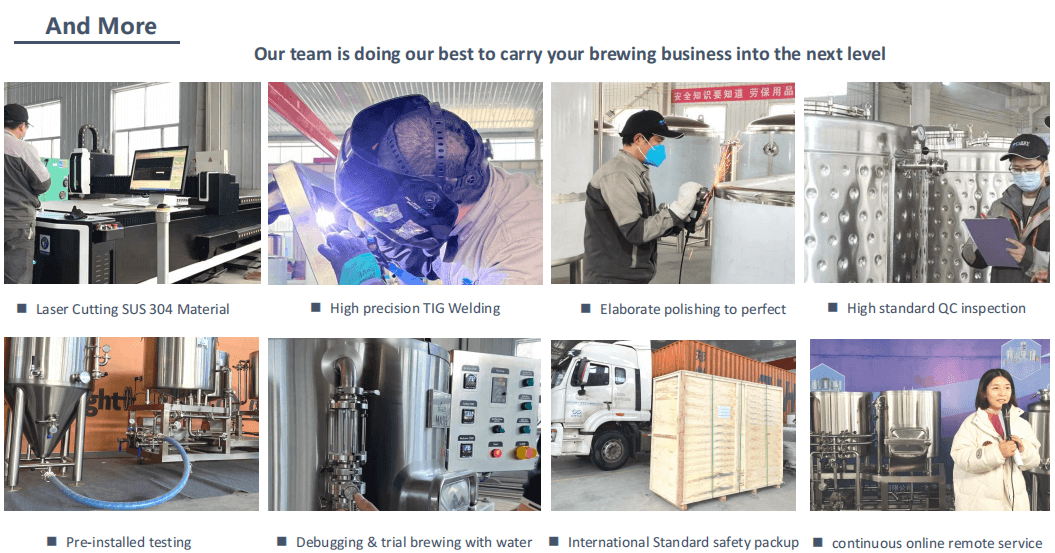

Packaging

Loading

Shipping

CARRY Brewtech 100L Pilot Brewing Equipment Brewing Kit is specially customized for homebrew hobbies, entry-level Micro Breweries, Pilot Brewing System, or a full-scale Nano-Brewery production.

Configuration:

Regarding the picture, that is customized 100L 3 vessel brewhouse.

-With Mash/Lauter tank, Kettle/Whirlpool Tank, Hot Liquor Tank, all tanks are 2-layer with insulation

--Mash tank is with false bottom, grain door, and so on

--Kettle tank is with whirlpool tangential inlet, electric element, and so on

--Hot liquor tank is with electric element mainly.

--With PLC controller

Hot Liquor Tank

Kettle/Whirlpool Tank

Mash/Lauter Tank

Heating method:

Standard brewhouse is heated by electric elements.

When brewing with electric, the heat is applied internally rather than externally (as with direct fire or steam jacket). The heating comes from electric elements which are housed in stainless steel sheathes inserted in your brewhouse vessels.

The main vessels in our brewhouse electric elements are kettle/whirlpool tank and hot liquor tank (HLT). You can have electric heating for your mash tun too. However, that’s a little trickier requiring its own section. Thus we suppgest that RIMS can help you in mash tank part.

Since, the elements are immersed in the liquid, virtually all of the energy applied to the elements, is transferred to heating your wort or water. Depending on the size of the brewhouse, you’ll usually have different KW elements per tank. Our 100L brewhouse is with 6kw electric elements for each tank.

Please don’t hesitate to contact us if you are interested in electric elements, looking forward to providing you with more services and support.

Comparing standard 100L brewhouse, ther are some difference as followsfor this customized 100L brewhouse:

1-Controller is changed. Generally it is with PID controller, this set is changed to PLC controller according to customers' requests

2-Add RIMS. That is more beneficial for brewers who like stepped mashing

3-Add Raker and Raker Motor. Standard brewhouse isn't fitted with raker motor, we will match a rake for you, and you can stir your wort by this rake

4-Position of electricity box is changed, Standard box is inside of the plateform frame, but PLC's box is too big to put it outside of the plateform frame

5-Updated Hop filter, and in the following days, this type will be our standard confirguration

PLC Controller

RIMS

Raker with Motor

Position of electricity box

Updated Hop Filter-Internal structure

Updated Hop Filter-External structure

Advantages

• Optional system volume from 100L to 200L

• Optional System power supply 110V/220V/380V/415V

• Total Frame mounted structure, convenient to move around

Packaging

Loading

Shipping