English

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

| Effective Volume: | |

|---|---|

| Heating Method: | Please select |

| Availability: | |

| Quantity: | |

2000L Commercial Kombucha Brewing Equipment

If you want to expand your Kombucha system, Carry Brewtech can supply the right equipment, training and service for your Industry. No matter how small or large your business is!

This system is mainly for boiling up water, and brew tea with sugar under proper temperature(85℃).

Brewing tea 10g per liter, adding sugar/80g per 1 liter

Heated by Gas type Steam Boiler

Heat exchanger to cool down liquid to First fermentation tank

Effective volume is 2000L, with steam heating design, you can have max to 2 batches brewing per day. This would be your best choice if you are after 4000L daily output system.

Our manufacturer can produce large range of products as you need, which is complete turnkey solution. Contact us now to get your unique system built from scratch to perfect!

2000L Tea Brewing Tank

2000L Hot Kettle Tank

| 2000L Hot Kettle Tank | |

1 | Effective volume= 2000L, total volume=2500L, Dimension=φ1660*2500mm, gross weight=350kg |

2 | Top manway |

3 | Equipped with Steam Heating Jacket between inner/outer jacket |

4 | Pressure Relief Valve on Top of tank |

5 | Temperature probe (PT-100) |

6 | Outdoor condensate collection pipe |

7 | with water flowmeter, Germany IFM brand |

8 | Level tube |

9 | 360° coverage CIP spraying ball |

10 | Double Layer: Inner-Jacket (SUS304), TH=3.0mm, pickling&passivating treated; External-Jacket(SUS 304), TH=2.0mm, ink wires drawing plate |

11 | ·Dish head (SUS304), TH=3.0mm. |

12 | ·Insulation layer: PU-thickness= 80mm. |

13 | ·100% high precision TIG welded joints |

14 | ·4pcs x SUS304 heavy duty legs with leveling pad |

| 2000L Tea Brewing Tank | |

1 | Effective volume= 1500L, total volume=2000L, Dimension=φ1660*2500mm, gross weight=450kg |

2 | Top Glass type manway(φ500mm) |

3 | Underneath driven Agitator with motor & reducer ( 2.2kw,VFD type) |

4 | Outdoor condensate collection pipe |

5 | 360° coverage CIP spraying ball |

6 | Side mounted Tea outdoor(manhole) , size=430*550mm |

7 | Tea/liquid drain port underneath of the tank |

8 | Temperature probe (PT-100) |

9 | Level Tube |

10 | With 10 m3/h Sanitary VFD Pump (transfering water and mixed tea) |

11 | Plate Heat Exchanger, BR0.1 / 18㎡ ·Cooling efficiency: from 90C to 28C in 40 mins·Sanitary type, 304 SUS Material·Design pressure:1.0 Mpa; ·Working temperature: 170°C.·Double-stage cooling type (ie. Hot tea &Glycol water & Tap water), to be update to single stage in future |

Brew tank with bottom agitator

Brew tank with bottom agitator  360° coverage CIP spraying ball

360° coverage CIP spraying ball  Outdoor condensing unit

Outdoor condensing unit  IFM Flow meter

IFM Flow meter  Plate Heat Exchanger

Plate Heat Exchanger  Steam heating pipeline with valves

Steam heating pipeline with valves

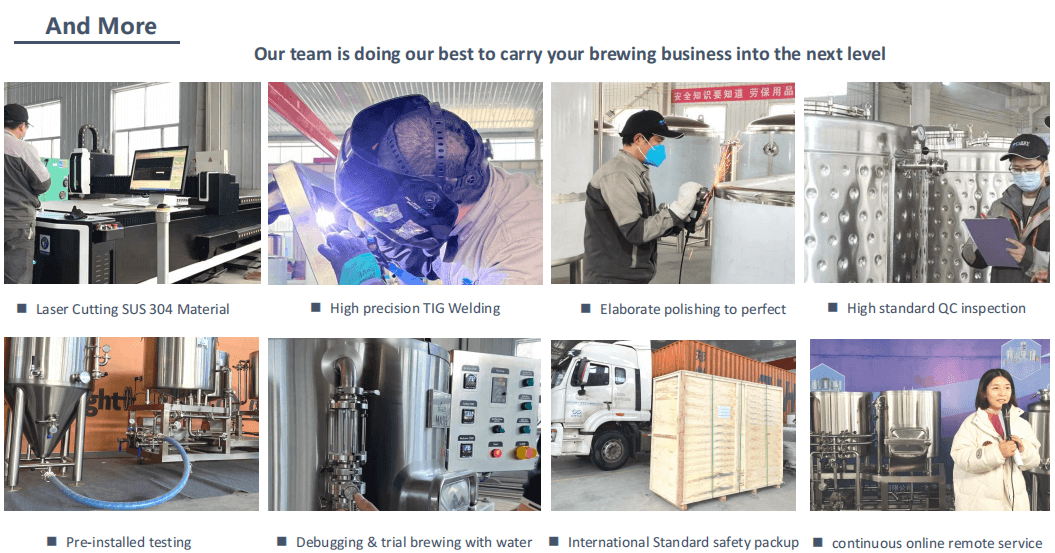

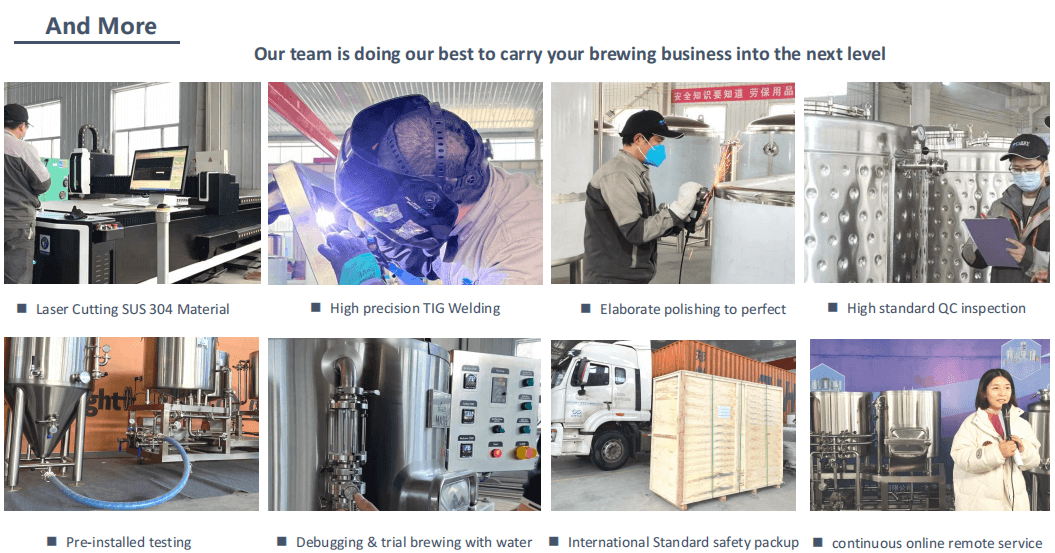

Carry Brewtech, the professional OEM manufacturer with more than 10 years of experience in the Beer & Kombucha Brewing & Fermenting equipment area.

1. Kombucha Brew center (100L~50HL, for boiling up water, brewing tea, and mixing with sugar)

2. Open-top fermenter (100L~50HL, for SCOBY fermenting under 27 Degrees Celsius)

3. Carbonation Tank (100L~50HL, forced carbonation of your brewed kombucha to get a fizzy taste)

4. Kombucha Filling Machine (Isobaric filling)

5. CIP sanitary cleaning system

6. Filtration System

7. Other Kombucha brewing accessories

8. Business Consultation service to start from scratch to perfect

Please don't hesitate to let us know if we can be of any assistance to your kombucha brewing business. Cheers!

Kombucha Open-Top fermenter (SCOBY Tank)

Kombucha Isobaric Filling Machine

2000L Commercial Kombucha Brewing Equipment

If you want to expand your Kombucha system, Carry Brewtech can supply the right equipment, training and service for your Industry. No matter how small or large your business is!

This system is mainly for boiling up water, and brew tea with sugar under proper temperature(85℃).

Brewing tea 10g per liter, adding sugar/80g per 1 liter

Heated by Gas type Steam Boiler

Heat exchanger to cool down liquid to First fermentation tank

Effective volume is 2000L, with steam heating design, you can have max to 2 batches brewing per day. This would be your best choice if you are after 4000L daily output system.

Our manufacturer can produce large range of products as you need, which is complete turnkey solution. Contact us now to get your unique system built from scratch to perfect!

2000L Tea Brewing Tank

2000L Hot Kettle Tank

| 2000L Hot Kettle Tank | |

1 | Effective volume= 2000L, total volume=2500L, Dimension=φ1660*2500mm, gross weight=350kg |

2 | Top manway |

3 | Equipped with Steam Heating Jacket between inner/outer jacket |

4 | Pressure Relief Valve on Top of tank |

5 | Temperature probe (PT-100) |

6 | Outdoor condensate collection pipe |

7 | with water flowmeter, Germany IFM brand |

8 | Level tube |

9 | 360° coverage CIP spraying ball |

10 | Double Layer: Inner-Jacket (SUS304), TH=3.0mm, pickling&passivating treated; External-Jacket(SUS 304), TH=2.0mm, ink wires drawing plate |

11 | ·Dish head (SUS304), TH=3.0mm. |

12 | ·Insulation layer: PU-thickness= 80mm. |

13 | ·100% high precision TIG welded joints |

14 | ·4pcs x SUS304 heavy duty legs with leveling pad |

| 2000L Tea Brewing Tank | |

1 | Effective volume= 1500L, total volume=2000L, Dimension=φ1660*2500mm, gross weight=450kg |

2 | Top Glass type manway(φ500mm) |

3 | Underneath driven Agitator with motor & reducer ( 2.2kw,VFD type) |

4 | Outdoor condensate collection pipe |

5 | 360° coverage CIP spraying ball |

6 | Side mounted Tea outdoor(manhole) , size=430*550mm |

7 | Tea/liquid drain port underneath of the tank |

8 | Temperature probe (PT-100) |

9 | Level Tube |

10 | With 10 m3/h Sanitary VFD Pump (transfering water and mixed tea) |

11 | Plate Heat Exchanger, BR0.1 / 18㎡ ·Cooling efficiency: from 90C to 28C in 40 mins·Sanitary type, 304 SUS Material·Design pressure:1.0 Mpa; ·Working temperature: 170°C.·Double-stage cooling type (ie. Hot tea &Glycol water & Tap water), to be update to single stage in future |

Brew tank with bottom agitator

Brew tank with bottom agitator  360° coverage CIP spraying ball

360° coverage CIP spraying ball  Outdoor condensing unit

Outdoor condensing unit  IFM Flow meter

IFM Flow meter  Plate Heat Exchanger

Plate Heat Exchanger  Steam heating pipeline with valves

Steam heating pipeline with valves

Carry Brewtech, the professional OEM manufacturer with more than 10 years of experience in the Beer & Kombucha Brewing & Fermenting equipment area.

1. Kombucha Brew center (100L~50HL, for boiling up water, brewing tea, and mixing with sugar)

2. Open-top fermenter (100L~50HL, for SCOBY fermenting under 27 Degrees Celsius)

3. Carbonation Tank (100L~50HL, forced carbonation of your brewed kombucha to get a fizzy taste)

4. Kombucha Filling Machine (Isobaric filling)

5. CIP sanitary cleaning system

6. Filtration System

7. Other Kombucha brewing accessories

8. Business Consultation service to start from scratch to perfect

Please don't hesitate to let us know if we can be of any assistance to your kombucha brewing business. Cheers!

Kombucha Open-Top fermenter (SCOBY Tank)

Kombucha Isobaric Filling Machine