English

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

| Availability: | |

|---|---|

| Quantity: | |

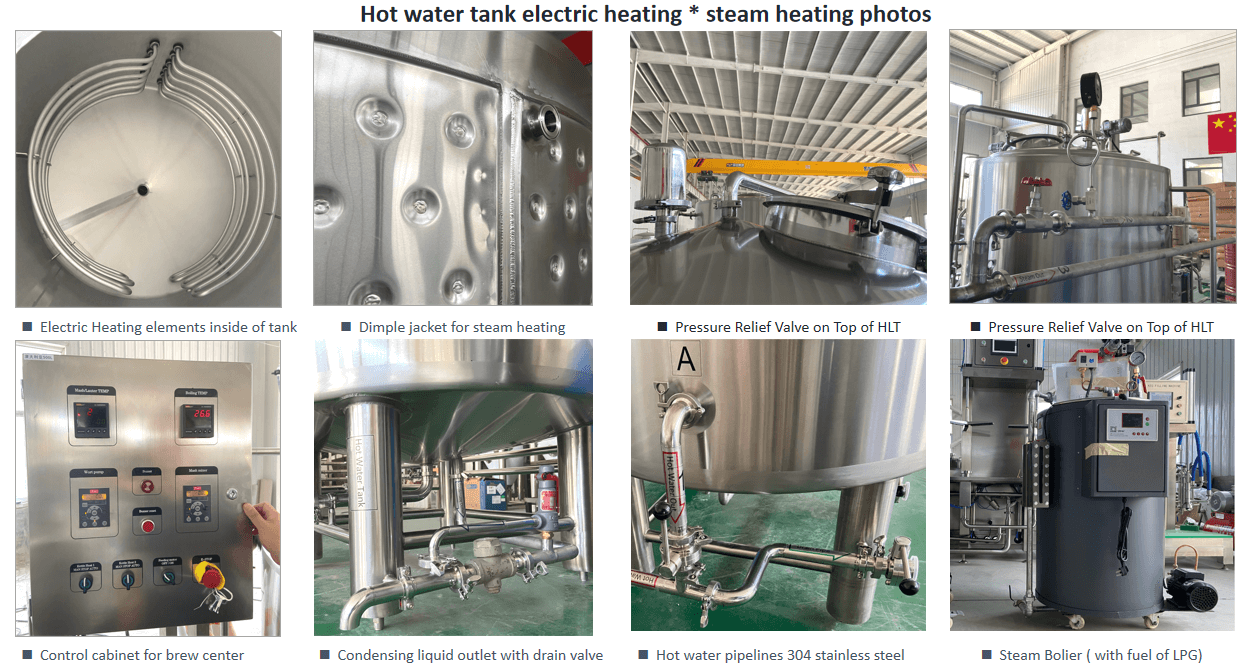

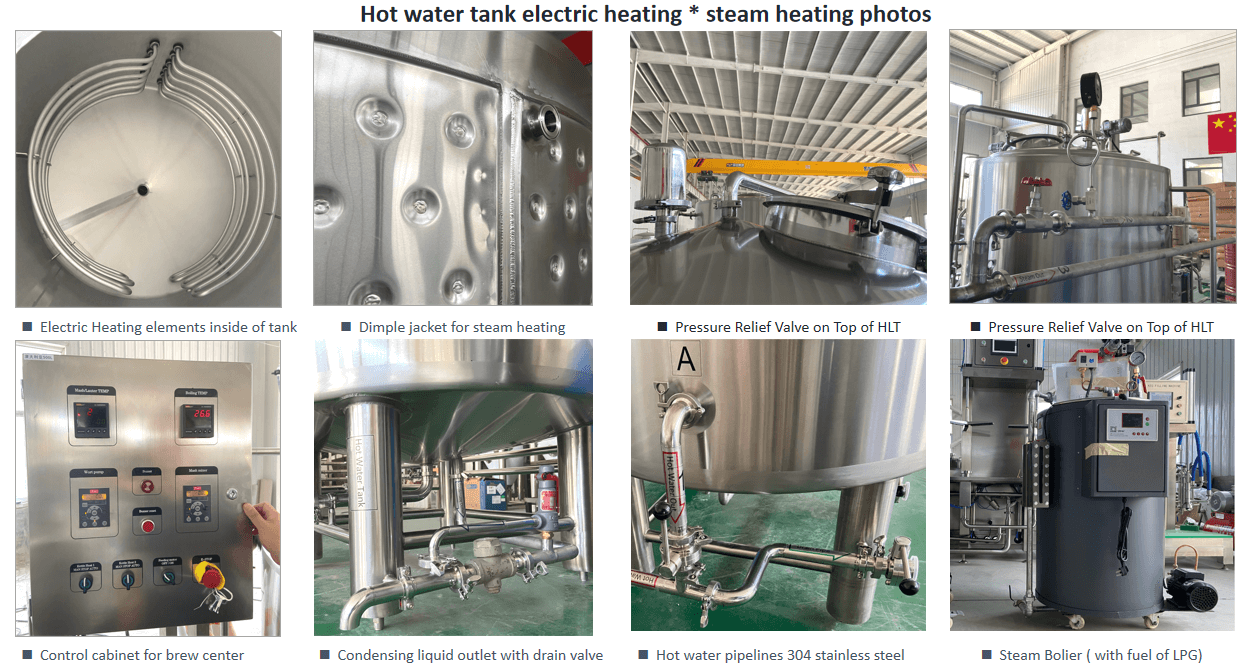

300L - 5000L Hot Liquor Tank & Hot Water Tank

A source of hot water is required for almost every process in the brewery, from mashing and sparging to cleaning and sanitization. Temperature control of water is critical, especially during the mashing process, because too high a temperature can result in off-flavors produced by tanks as well as possibly killing the entire sugar conversion process. If the temperature is too low, the sugar conversion process will not even begin, resulting in a weaker beer in terms of both flavor and alcohol content. Both scenarios result in not only a waste of raw materials but also a waste of manpower, as an entire brew day is lost. It's also worth noting that different beer styles necessitate different mashing and sparging temperatures. As a result, a properly equipped Hot Liquor Tank (HLT) is critical to your brewery.

1) Capacity: 300 liter to 5000L liter as requirement.

2) Material: stainless steel 304, as requirement.

3) General configuration: mill, brew house, fermentation, cooling and cleaning etc.

4) Heating principle: electric heating, steam heating, gas fire etc.

5) Electricity voltage/frequency can be customized.

6) Running in a high automatization and intellectualization,no pollution.

*Interior Shell: SUS304 TIG welded; TH=3mm

*Exterior Shell: SUS304 TIG welded; TH=2mm

*100% TIG welding with pure argon gas shield

*Interior full polished to 0.6 μm without dead corner

*Insulated with high density Polyurethane foam; TH=80mm

*Stringent tank leakage test by water

*Insulated conical top and bottom

*Top mounted stainless steel manway with door

*Thermowell for high accuracy temperature sensor

*4pcs completely SUS304 heavy duty legs with leveling pad

It is used to provide hot water to Brewhouse, used in saccharification and filtration, used to clean wort and filter wort, and also commonly used in CIP cleaning system, used to clean fermentation tanks, sake tanks, and other beer fermentation equipment

Packaging Details

Inner stretching membrane and PE paper and outer steel frame, and other packaging for shipping.

1. Main beer brewing tanks, fermenting vessels and turnkey brewhouse system will be packaged with plastic film firstly, then with reinforced steel frames.

2. All beer brewing spare parts, accessories and fittings will be packaged with carton box and crated.

3. All items wrapped with soft package for protection.

4. Each parts of whole brewing system will be labeled.

Port: Qingdao Port, Shanghai Port, Shenzhen Port

Founded in 2017, Carry Brewtech has been supplying all kinds of customized Brewhouse, Fermenter, Bright tank, brewery auxiliaries, and system turnkey solutions to more than 800 customers all over the world, industries including Beer, Kombucha, Wine, Gin, Rum, etc. With continuous R&D, innovation, value-driven, you'll be served by the most cost-effective and suitable custom solution from our knowledgeable team. Carry Brewtech takes pride in supplying the right equipment, training, and service for your Industry. No matter how small or large your business is!

300L - 5000L Hot Liquor Tank & Hot Water Tank

A source of hot water is required for almost every process in the brewery, from mashing and sparging to cleaning and sanitization. Temperature control of water is critical, especially during the mashing process, because too high a temperature can result in off-flavors produced by tanks as well as possibly killing the entire sugar conversion process. If the temperature is too low, the sugar conversion process will not even begin, resulting in a weaker beer in terms of both flavor and alcohol content. Both scenarios result in not only a waste of raw materials but also a waste of manpower, as an entire brew day is lost. It's also worth noting that different beer styles necessitate different mashing and sparging temperatures. As a result, a properly equipped Hot Liquor Tank (HLT) is critical to your brewery.

1) Capacity: 300 liter to 5000L liter as requirement.

2) Material: stainless steel 304, as requirement.

3) General configuration: mill, brew house, fermentation, cooling and cleaning etc.

4) Heating principle: electric heating, steam heating, gas fire etc.

5) Electricity voltage/frequency can be customized.

6) Running in a high automatization and intellectualization,no pollution.

*Interior Shell: SUS304 TIG welded; TH=3mm

*Exterior Shell: SUS304 TIG welded; TH=2mm

*100% TIG welding with pure argon gas shield

*Interior full polished to 0.6 μm without dead corner

*Insulated with high density Polyurethane foam; TH=80mm

*Stringent tank leakage test by water

*Insulated conical top and bottom

*Top mounted stainless steel manway with door

*Thermowell for high accuracy temperature sensor

*4pcs completely SUS304 heavy duty legs with leveling pad

It is used to provide hot water to Brewhouse, used in saccharification and filtration, used to clean wort and filter wort, and also commonly used in CIP cleaning system, used to clean fermentation tanks, sake tanks, and other beer fermentation equipment

Packaging Details

Inner stretching membrane and PE paper and outer steel frame, and other packaging for shipping.

1. Main beer brewing tanks, fermenting vessels and turnkey brewhouse system will be packaged with plastic film firstly, then with reinforced steel frames.

2. All beer brewing spare parts, accessories and fittings will be packaged with carton box and crated.

3. All items wrapped with soft package for protection.

4. Each parts of whole brewing system will be labeled.

Port: Qingdao Port, Shanghai Port, Shenzhen Port

Founded in 2017, Carry Brewtech has been supplying all kinds of customized Brewhouse, Fermenter, Bright tank, brewery auxiliaries, and system turnkey solutions to more than 800 customers all over the world, industries including Beer, Kombucha, Wine, Gin, Rum, etc. With continuous R&D, innovation, value-driven, you'll be served by the most cost-effective and suitable custom solution from our knowledgeable team. Carry Brewtech takes pride in supplying the right equipment, training, and service for your Industry. No matter how small or large your business is!