English

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

| Effective Volume: | |

|---|---|

| Combination: | |

| Availability: | |

| Quantity: | |

Carry Brewtech 30HL 4-vessel Brewhouse system is the ideal designed specically for medium sized Industrial-breweries that want to produce on a large scale with a relatively compact footprint and have the flexibility to brew a large range of styles.

Customized Solution

Compact Structure

Fully Sanitary 304 material

If you are scheduling the next Industrial brewing system, please don't hesitate to let us know. Carry Brewtech team is happy to provide FREE and CUSTOMIZED solution for you.

Optional Combination:

Effective production capacity per batch: 1000L, 10BBL, 20HL, 20BBL, 30HL, 30BBL, 50HL, Customized

Structure:

A - Mash Tank + Lauter Tank + Kettle/Whirlpool Tank + 2-times HLT [Recommend for 2-batch brewday]

B - Mash/Lauter Tank + Kettle Tank + Whirlpool Tank + 2-times HLT

C - Mash Tank + Lauter Tank + Kettle Tank + Whirlpool Tank + 2-times HLT (5-Vessel system)

A- MASH TANK

30HL Mash tank with extra 20% head space

Dish head with top mounted glass manway (with your LOGO etched)

LED Light comes included in the tank, easy inside-checking between batches

CIP Spray Ball equipped with CIP Arm, butterfly valve on the end

Hydrator with customized grist case

Bottom driven Agitator, VFD speed control

Steam heating jacket on the cone and side

Individual Mash pump to transfer mash to the Lauter tank

B- LAUTER TANK

30HL Lauter tank with extra 20% head space

Dish head with top mounted glass manway (with your LOGO etched)

LED Light on top of dish head

Bottom driven Grain rake with auto grain-out device, VFD speed control

Sieve plate

Bottom grain out port with pneumatic knife valve installed

Bottom based wort collection pipe and back flushing pipeline

Balance colume with sight glass and sample valve on top of platform

Individual Lauter pump to transfer wort to the kettle tank

C- KETTLE/WHIRLPOOL TANK

Heating method: Steam heating jacket on cone, side, and inside of tank (steam colume)

Tangential Whirlpool inlet equip on 1/3 position of kettle tank

Top mounted Steam condensing pipe (outdoor)

Top mounted glass manway (with your LOGO etched)

LED Light comes included in the tank, easy inside-checking between batches

CIP Spray Ball equipped with CIP Arm, butterfly valve on the end, easy to attach to your CIP Cart for cleaning ideally

Individual Whirlpool pump to generate whirlpool effect and knocking out the worts into FVs, VFD speed control

Complete Platform with stairs and guiderails

Pre-build Control System on side of tanks

Bottom driven grain rake with auto-out device

Bottom grain out port with pneumatic valve

Build-in steam heating colume for Kettle tank

Dual wort filter (tri-clamp) before PHE

Sight glass with level marks

Glass manhole with your LOGO etched

30HL Brewhouse Side View

30HL 4-Vessel Brewhouse Top View

For brewery system that will be setup in pub or restaurant, it has more factors need to be taken in to consideration:

1. Attractive

Brewery system is not only the equipment that provide beers, but also an art corner to attract clients. So, you need to consider the option that looks nice.

2. Save your time

Once you own your pub, the most treasureable thing would be your time, you need time to brew beers, finalize marketing, visit your clients, and manage the cash flow. Everybody has 24 hours a day, but you were trying to split it into 48 hours.

So, if there is a system can help you optimize the operation process, save your time to do more worthful works, then don't hesitate, that is the suitable one for you.

3. Turnkey solution

Recently, COVID-19 makes the travels difficult, especially when your system need the onsite installation service. But how to install?

Don't worry, if you can find a supplier that can provide turnkey solution, don't miss it. That will be the wonderful option at the moment.

From the owner’s point of view, all of them are important to start with. So sourcing the right supplier will be an significant choice. Carry brewtech provides consultation service from 0 to 1.

Contact CARRY guys right now, we are ready to provide the most suitable solutions for your business. Let’s do it!

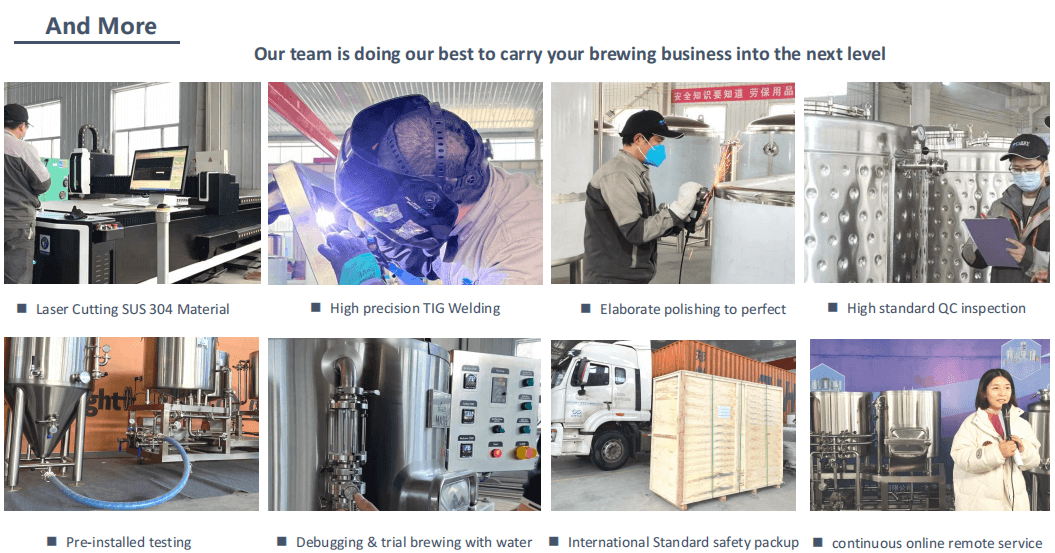

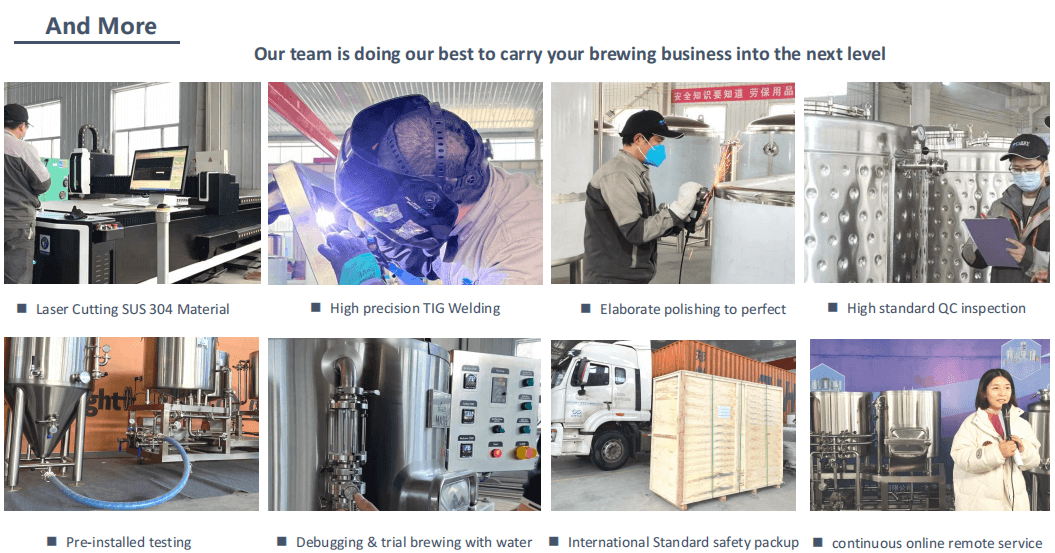

Listen -> communication -> system configuration -> layout -> simulated pipeline -> Details -> price quotation -> production -> shipment -> remote/onsite service -> life-time support

Carry Brewtech 30HL 4-vessel Brewhouse system is the ideal designed specically for medium sized Industrial-breweries that want to produce on a large scale with a relatively compact footprint and have the flexibility to brew a large range of styles.

Customized Solution

Compact Structure

Fully Sanitary 304 material

If you are scheduling the next Industrial brewing system, please don't hesitate to let us know. Carry Brewtech team is happy to provide FREE and CUSTOMIZED solution for you.

Optional Combination:

Effective production capacity per batch: 1000L, 10BBL, 20HL, 20BBL, 30HL, 30BBL, 50HL, Customized

Structure:

A - Mash Tank + Lauter Tank + Kettle/Whirlpool Tank + 2-times HLT [Recommend for 2-batch brewday]

B - Mash/Lauter Tank + Kettle Tank + Whirlpool Tank + 2-times HLT

C - Mash Tank + Lauter Tank + Kettle Tank + Whirlpool Tank + 2-times HLT (5-Vessel system)

A- MASH TANK

30HL Mash tank with extra 20% head space

Dish head with top mounted glass manway (with your LOGO etched)

LED Light comes included in the tank, easy inside-checking between batches

CIP Spray Ball equipped with CIP Arm, butterfly valve on the end

Hydrator with customized grist case

Bottom driven Agitator, VFD speed control

Steam heating jacket on the cone and side

Individual Mash pump to transfer mash to the Lauter tank

B- LAUTER TANK

30HL Lauter tank with extra 20% head space

Dish head with top mounted glass manway (with your LOGO etched)

LED Light on top of dish head

Bottom driven Grain rake with auto grain-out device, VFD speed control

Sieve plate

Bottom grain out port with pneumatic knife valve installed

Bottom based wort collection pipe and back flushing pipeline

Balance colume with sight glass and sample valve on top of platform

Individual Lauter pump to transfer wort to the kettle tank

C- KETTLE/WHIRLPOOL TANK

Heating method: Steam heating jacket on cone, side, and inside of tank (steam colume)

Tangential Whirlpool inlet equip on 1/3 position of kettle tank

Top mounted Steam condensing pipe (outdoor)

Top mounted glass manway (with your LOGO etched)

LED Light comes included in the tank, easy inside-checking between batches

CIP Spray Ball equipped with CIP Arm, butterfly valve on the end, easy to attach to your CIP Cart for cleaning ideally

Individual Whirlpool pump to generate whirlpool effect and knocking out the worts into FVs, VFD speed control

Complete Platform with stairs and guiderails

Pre-build Control System on side of tanks

Bottom driven grain rake with auto-out device

Bottom grain out port with pneumatic valve

Build-in steam heating colume for Kettle tank

Dual wort filter (tri-clamp) before PHE

Sight glass with level marks

Glass manhole with your LOGO etched

30HL Brewhouse Side View

30HL 4-Vessel Brewhouse Top View

For brewery system that will be setup in pub or restaurant, it has more factors need to be taken in to consideration:

1. Attractive

Brewery system is not only the equipment that provide beers, but also an art corner to attract clients. So, you need to consider the option that looks nice.

2. Save your time

Once you own your pub, the most treasureable thing would be your time, you need time to brew beers, finalize marketing, visit your clients, and manage the cash flow. Everybody has 24 hours a day, but you were trying to split it into 48 hours.

So, if there is a system can help you optimize the operation process, save your time to do more worthful works, then don't hesitate, that is the suitable one for you.

3. Turnkey solution

Recently, COVID-19 makes the travels difficult, especially when your system need the onsite installation service. But how to install?

Don't worry, if you can find a supplier that can provide turnkey solution, don't miss it. That will be the wonderful option at the moment.

From the owner’s point of view, all of them are important to start with. So sourcing the right supplier will be an significant choice. Carry brewtech provides consultation service from 0 to 1.

Contact CARRY guys right now, we are ready to provide the most suitable solutions for your business. Let’s do it!

Listen -> communication -> system configuration -> layout -> simulated pipeline -> Details -> price quotation -> production -> shipment -> remote/onsite service -> life-time support