English

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

No.21-2 of Jiyang Industrial Park, Jiyang District, Jinan, Shandong, China

| Effective Volume: | |

|---|---|

| Heating Method: | Please select |

| Availability: | |

| Quantity: | |

CR-BM500L

CARRY

CR-BM500L

500L Combined 2 Vessel Brewhouse and 2 Vessel 3 Tank Brewing System Beer Brewing Equipment System Manufacturer

This brewhouse set includes combined 2 vessel, powered by steam heating. This brewhouse set can satisfy your different brewing requests, just like single-step mashing infusion, stepped mashing infusion and so on. Some friends name it 2 vessel 3 tank because it has 3 individual tank.

#1 Vessel: Top is Mash/Lauter Tank, Bottom is Whirlpool Tank

#2 Vessel: Boil Tank

If you have your Pub running, or the scale of your current brewery(50L~200L brewery) couldn’t meet your market needs and looking for an affordable brewery system with small footprint, don’t miss this out, 500L combined 2 Vessel will be a great choice for you.

There are some details of 500L combined 2 Vessel brewhosue mainly.

|

| 1. | CIP Arm | 10. | Wort Oxgenation Device |

| 2. | Raker & Motor with VFD | 11. | Kettle/Whirlpool Tank |

| 3. | Sight Glass | 12. | Tangential Whirlpool Inlet |

| 4. | Top Manhole | 13. | Platform with guardrail |

| 5. | Balanced Tank | 14. | Food-grade Wort Pump |

| 6. | Condensing Unit | 15. | Pallet&Tray(optional) |

| 7. | Level Gauge | 16. | Grain Door |

| 8. | Plate Heating Exchanger | 17. | Mash/Lauter Tank |

| 9. | Yeast Adding Tank | 18. | Piping and accessories |

Mash/Lauter Tun(Top tank)

Whirlpool Tank(Bottom tank)

a. Effective volume= 500L, total volume= 625L

b. Top Manway

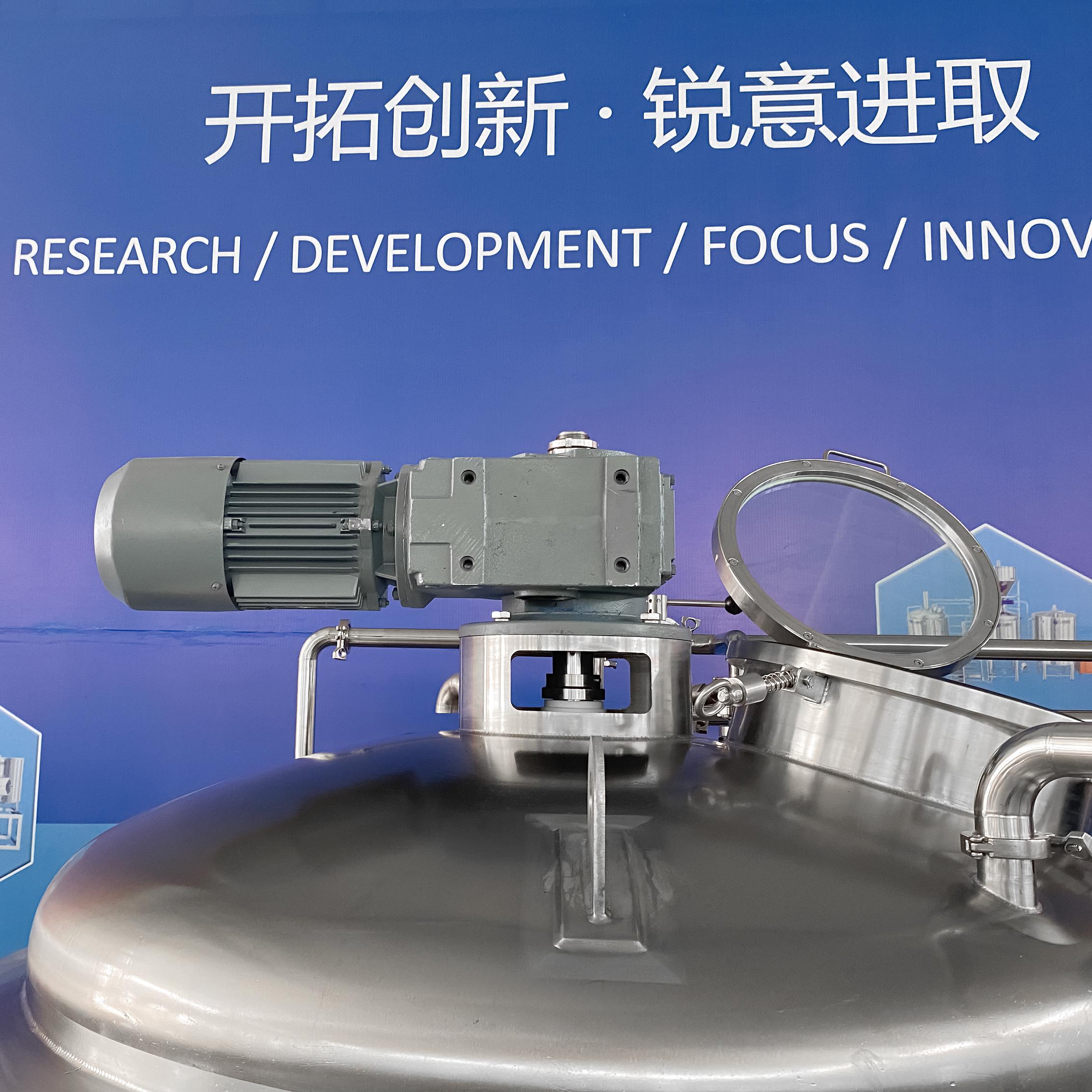

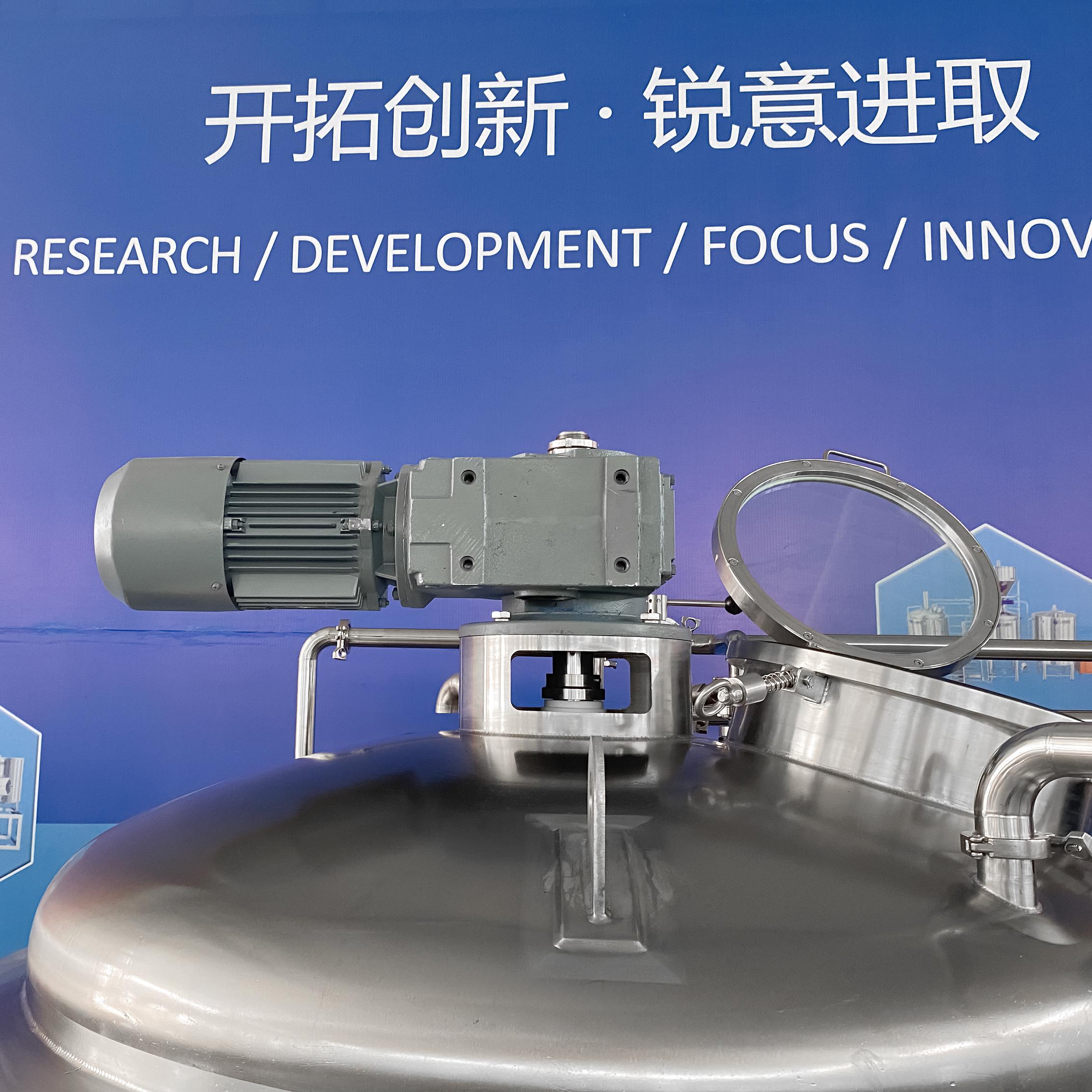

c. Rake with VFD 1.1KW Motor & reducer

d. Spray ring & 360° coverage CIP spraying ball

e. Side grain outdoor

f. High precision milled false bottom/sieve

g. Wort collection Ring pipes installed underneath

Kettle Tank (right)

Composed with standard brewhouse, here are some difference for this set of 500L combined brewhouse, just like followings.

1-2 vinasse door design, its angle can be customized according to brewing needs

2-Updated Raker&Raker Motor, more powerful

3-Customized whirlpool bottom. Standard is fitted with 160 conical bottom. If you like this type, let’ s chat further details together.

4-Condensing device is fitted with indoor condensing pipe only according clients’ requests.

5-Brewhouse Pipeline is specially designed as well.

If you want to ask about this brewhouse, or need any other tech specifications,just leave your message/questions on the comment area or email. CARRY Team will contact with you ASAP.

Anyway, just follow us, we will share lots of tips and advice on how to use all our beer brewing equipment.

Following is details of part.

Side details of Mash.Lauter Tank, Kettle Tank

Raker Motor Details

Side Spent Grain Door

Side Spent Grain Door

Raker Details in Mash/Lauter Tank

360° CIP Ball

Delievery & Feedback

Preparing Wooden Ccase

Moving Tanks

Moving Platform

Seal Box

Delivery Good

500L Combined 2 Vessel Brewhouse and 2 Vessel 3 Tank Brewing System Beer Brewing Equipment System Manufacturer

This brewhouse set includes combined 2 vessel, powered by steam heating. This brewhouse set can satisfy your different brewing requests, just like single-step mashing infusion, stepped mashing infusion and so on. Some friends name it 2 vessel 3 tank because it has 3 individual tank.

#1 Vessel: Top is Mash/Lauter Tank, Bottom is Whirlpool Tank

#2 Vessel: Boil Tank

If you have your Pub running, or the scale of your current brewery(50L~200L brewery) couldn’t meet your market needs and looking for an affordable brewery system with small footprint, don’t miss this out, 500L combined 2 Vessel will be a great choice for you.

There are some details of 500L combined 2 Vessel brewhosue mainly.

|

| 1. | CIP Arm | 10. | Wort Oxgenation Device |

| 2. | Raker & Motor with VFD | 11. | Kettle/Whirlpool Tank |

| 3. | Sight Glass | 12. | Tangential Whirlpool Inlet |

| 4. | Top Manhole | 13. | Platform with guardrail |

| 5. | Balanced Tank | 14. | Food-grade Wort Pump |

| 6. | Condensing Unit | 15. | Pallet&Tray(optional) |

| 7. | Level Gauge | 16. | Grain Door |

| 8. | Plate Heating Exchanger | 17. | Mash/Lauter Tank |

| 9. | Yeast Adding Tank | 18. | Piping and accessories |

Mash/Lauter Tun(Top tank)

Whirlpool Tank(Bottom tank)

a. Effective volume= 500L, total volume= 625L

b. Top Manway

c. Rake with VFD 1.1KW Motor & reducer

d. Spray ring & 360° coverage CIP spraying ball

e. Side grain outdoor

f. High precision milled false bottom/sieve

g. Wort collection Ring pipes installed underneath

Kettle Tank (right)

Composed with standard brewhouse, here are some difference for this set of 500L combined brewhouse, just like followings.

1-2 vinasse door design, its angle can be customized according to brewing needs

2-Updated Raker&Raker Motor, more powerful

3-Customized whirlpool bottom. Standard is fitted with 160 conical bottom. If you like this type, let’ s chat further details together.

4-Condensing device is fitted with indoor condensing pipe only according clients’ requests.

5-Brewhouse Pipeline is specially designed as well.

If you want to ask about this brewhouse, or need any other tech specifications,just leave your message/questions on the comment area or email. CARRY Team will contact with you ASAP.

Anyway, just follow us, we will share lots of tips and advice on how to use all our beer brewing equipment.

Following is details of part.

Side details of Mash.Lauter Tank, Kettle Tank

Raker Motor Details

Side Spent Grain Door

Side Spent Grain Door

Raker Details in Mash/Lauter Tank

360° CIP Ball

Delievery & Feedback

Preparing Wooden Ccase

Moving Tanks

Moving Platform

Seal Box

Delivery Good